A circular economy reimagines how we design, use, and repurpose materials, shifting away from the traditional “take-make-dispose” model toward systems that prioritize reuse and regeneration and provide long-term value. Inspired by nature’s closed-loop processes, this approach emphasizes resource efficiency, waste reduction, and environmental resilience.

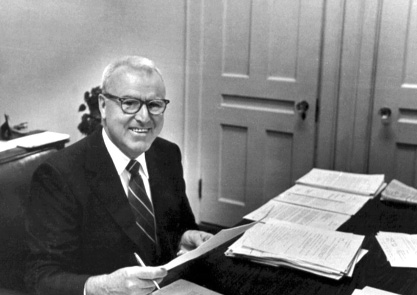

At Weston, this mindset is more than a framework—it’s a continuation of our founder’s vision. Roy F. Weston believed “to enhance the quality of a man’s life through the creative and sound use of human, economic, and natural resources, advanced science, and applied technology.” That philosophy still guides our work today, from brownfield redevelopment to per- and polyfluoroalkyl substances (PFAS) remediation and beyond.

Foundations of the Circular Thinking

The concept of circularity has evolved over the past century, rooted in early ideas from industrial ecology and environmental economics. It gained momentum in the late 1970s through the work of Walter Stahel and Genevieve Reday, who introduced the notion of a closed-loop system designed to extend product lifecycles and minimize waste.

Over time, this framework has been enriched by influential models such as cradle-to-cradle design, which promotes materials that can safely return to the environment or be reused; biomimicry, which draws on nature’s processes to inspire sustainable design; and the performance economy, which shifts value from ownership to service, encouraging durability and repairability.

Staying True to Weston’s Legacy

Roy F. Weston was a pioneer in environmental engineering whose visionary work helped lay the foundation for what we now recognize as circularity. Long before the term entered mainstream discourse, Mr. Weston championed the idea that environmental protection must be seamlessly integrated with economic development. His mission reflected a deep understanding of circular thinking—an approach that emphasizes designing systems to regenerate rather than deplete.

This philosophy was evident in his early work, which anticipated many of the principles now central to the circular economy, and is still evident in the work our team does today. The Weston team has led groundbreaking efforts in fields that exemplify the shift from linear to circular systems, including:

- Industrial wastewater treatment;

- Hazardous waste remediation; and

- Resource recovery.

For instance, our pioneering biological treatment systems for clients like Rohm and Haas Company and Shell Chemicals played a key role in restoring the Houston Ship Channel. These projects demonstrated how thoughtful design and recovery could keep materials in use, reduce waste, and support a more resilient and sustainable future.

Throughout his career, Mr. Weston’s projects consistently emphasized resource recovery, waste minimization, and the reuse of materials. Whether designing municipal incinerators that met U.S. Environmental Protection Agency (EPA) standards or developing advanced treatment systems for industrial effluents, his work went beyond regulatory compliance; it was about creating regenerative systems that could sustain both industry and the environment.

At the heart of this approach was a belief in excellence through people and performance. Mr. Weston famously stated, “A professional service organization can be no better than the average of its employees” and “Effort can earn praise—results earn money.” This results-driven ethos fueled a multidisciplinary approach to problem-solving that prioritized measurable impact over rhetoric. Mr. Weston didn’t just talk about sustainability—he engineered it. His work bridged the gap between environmental ideals and practical implementation, optimizing the balance between public and private enterprise, energy use, environmental quality, and economics.

In doing so, Roy F. Weston not only anticipated the circular economy—he helped build its foundation.

Turning Waste into Opportunity

At Weston, waste is not an endpoint—it’s a starting point for innovation. This philosophy continues to guide our approach to environmental challenges, transforming liabilities into assets through practical, science-based solutions. Today, Weston continues to apply circular principles across a range of services. Our stormwater management and water reuse strategies are designed to reduce runoff, recharge aquifers, and minimize the need for new water extraction, creating regenerative water cycles that align with circular goals. In the field, we’ve deployed machine learning and artificial intelligence (AI) to optimize munitions removal and reduce unnecessary excavation, preserving natural landscapes and minimizing waste. Through these integrated efforts, we’re not just managing environmental impact—we are redefining what’s possible through sustainable innovation.

Brownfield Redevelopment and Landfill Reuse

Weston has long championed the transformation of contaminated or underutilized land into productive assets. Our brownfield remediation projects reduce the need for new development, preserve ecosystems, and enable sustainable redevelopment such as green manufacturing hubs or renewable energy installations. In some cases, we have even capped landfills and repurposed them for solar energy generation, demonstrating how circular thinking can be applied at scale to infrastructure and land use.

PFAS Remediation and Resource Recovery

True to our roots in sustainability and innovation, Weston focuses on addressing PFAS with the best available tools and an innovator’s mindset. Our approach to remediating new contaminants does not preclude the use of “old” technologies. For example, we have successfully implemented PFAS remediation using novel applications of common wastewater technologies, delivering not only fiscally sustainable results for our clients and communities but also exceeding compliance goals. With more than 20 years of experience investigating and remediating PFAS, we understand the value of engineering solutions that preserve the precious resources and environment and do not rely solely on conventional approaches that may not deliver the best results.

Lithium-Ion Battery Recovery and Circular Innovation

Weston is at the forefront of advancing circular solutions for lithium-ion battery (LIB) recovery, particularly in addressing the growing complexities of managing damaged, defective, or recalled batteries in challenging environments. Moving beyond conventional methods that focus solely on containment, Weston’s strategy emphasizes on-site risk reduction and material recovery.

Our approach leverages innovative field techniques—including de-energization and safe deconstruction—to neutralize battery hazards and enable efficient recycling of critical metals. By transforming hazardous waste into valuable resources, we not only mitigate environmental and safety risks but also help to close the loop on essential minerals, supporting a more resilient and sustainable supply chain. This scalable model demonstrates how proactive, science-driven solutions can redefine best practices for battery lifecycle management across the industry.

Construction Material Reuse

We actively integrate recycled and repurposed materials into our engineering and construction practices—a core tenet of the circular mindset. Weston’s primary goals are to reduce reliance on virgin resources, lower greenhouse gas emissions, and extend the lifecycle of built assets.

While we do not operate recycling facilities, our field teams and project managers consistently identify opportunities to reuse materials on-site and source sustainable alternatives. Our approach includes:

- Facility Decommissioning and Remediation: We expertly characterize and manage the reuse or safe disposal of building materials like concrete, insulation, and structural steel. This ensures full compliance with environmental regulations while significantly minimizing waste.

- Infrastructure Upgrades: In projects across multiple states, our construction teams reuse existing structural elements and repurpose materials, such as pavement and bollards, to efficiently meet updated safety and accessibility standards.

- Large-Scale Environmental Restoration: We frequently reuse stabilized soils and sediment for backfill or site grading. This practice reduces the need for off-site disposal and new material sourcing.

These circular practices not only support sustainability goals but also deliver tangible cost savings and logistical efficiencies for our clients.

Internal Commitment to Circularity

At Weston, our commitment to sustainability extends beyond client work and into the core of our operations. Internally, our environment, social, and governance (ESG) initiatives emphasize closed-loop procurement and energy-efficient design, reflecting our dedication to reducing dependency on virgin resources and regenerating value across systems. We have implemented environmentally preferred practices across our offices, such as sourcing equipment through EPA Green Criteria, offering electric vehicle (EV) charging stations, and using energy-efficient appliances and motion-sensor lighting to lower our corporate carbon footprint.

Our hybrid work model and digital-first communication strategies further reduce travel-related emissions and resource use. Meanwhile, our lifecycle asset management services help clients extend the usable life of infrastructure and reduce resource consumption, demonstrating how circular principles can be embedded in both our internal operations and external solutions. By designing systems that align with long-term sustainability goals, Weston shows that environmental stewardship truly begins at home.

Looking Ahead

The path forward is not about abstract ideals—it’s about practical, scalable solutions. By aligning our services with circular principles, Weston helps clients reduce risk, unlock value, and build more resilient communities. Whether it’s through brownfield transformation, innovative remediation, or sustainable redevelopment, we are helping shape a future where environmental responsibility and economic vitality go hand in hand.

Frequently Asked Questions: The Circular Economy

A circular economy is an economic system designed to eliminate waste and the unsustainable use of finite resources. It stands in direct contrast to the traditional linear economy, which follows a “take-make-dispose” pattern. The primary circular economy aims are to keep products and materials in use for as long as possible, decoupling economic growth from natural resource extraction. This circular economy approach protects the natural environment by minimizing pollution and waste.

The circular economy transition is guided by three main principles:

- Regenerate natural systems, such as returning safe, biological materials to the soil to improve land health, thereby supporting biodiversity.

- Design out waste and environmental pollution from the very beginning of a product’s entire lifecycle.

- Keep products and existing materials in circulation at their highest value through reuse, repair, refurbishment, and finally, recycling existing materials.

There are many compelling reasons why the circular economy is gaining importance—and why organizations and business owners should pay attention:

- Resilience and Risk Management: Circular businesses are often more resilient to shocks, such as supply chain disruptions or price spikes, because they rely more on local, reused, or recycled inputs.

- Resource Scarcity and Cost Volatility: Natural resources are becoming more difficult and more expensive to extract. A circular economy reduces dependency on virgin materials by promoting reuse, recycling, and remanufacturing, which helps businesses stabilize costs and secure supply chains.

- Regulatory Pressure: Governments around the world are introducing stricter regulations on waste, packaging, and product lifecycle responsibility. Embracing circular practices helps businesses stay ahead of compliance and avoid penalties.

- Economic Opportunity and Innovation: Circular models open up new revenue streams—like product-as-a-service, repair services, or resale markets. They also drive innovation in design, materials, and business models, giving companies a competitive edge.

- Changing Consumer Expectations: Consumers—especially younger generations—are increasingly valuing sustainability. Businesses that adopt circular principles can build brand loyalty, attract conscious customers, and differentiate themselves in crowded markets.

- Operational Efficiency: Circular practices often lead to leaner operations, reduced waste, and lower energy use. This can translate into cost savings and improved margins over time.