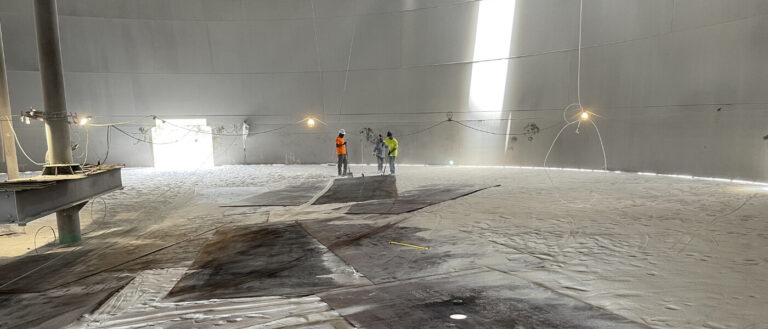

In 2007, a fuel release at UTF impacted the waters of Pearl Harbor. Since then, the Department of the Navy has taken steps to inspect and repair the aboveground storage tanks (ASTs) as it also conducts programming for inspection and repair of the underground storage tanks at Red Hill. Because of national security concerns, the volume of fuel storage in Hawaii cannot drop below predetermined limits, which would occur if tanks were taken out of service for extended periods of time. To address this issue, Weston was contracted to perform emergent repairs to one of the tanks at UTF. Our primary objective was to perform specified API 653 out-of-service inspection repairs to AST 47 per the government-provided API 653 report. Tank 47 is located at the Naval Supply Systems Command Fleet Logistics Center UTF at Joint Base Pearl Harbor-Hickam and serves as a transfer station, connecting Red Hill Storage, dockside issue and receipt, and Hickam Air Force Base.

Weston conducted a comprehensive inspection of Tank 47 and made timely recommendations for mandatory repairs to prevent the potential for fuel releases.The tanks at UTF were constructed in 1925, and are over 90 years old. Repairing the tanks required craftsman-quality metal work to retrofit off-the-shelf materials onto these antique tanks. The potential for corrosion requires that the tank shell be carefully examined to look for areas of perforations not found in modern tanks.

Mechanical repairs to Tank 47 included repair of five corroded roof columns that support the roof of the tank and refurbishing all tank isolation valves. While the tank was out of service, minor repairs were completed to achieve compliance with the United Facilities Criteria Code, including modifying the Automatic Tank Gauge stilling well to contain 1-inch diameter openings installed flush to the bottom plate and rerouting the issue pipe from above sump to follow current approved military design. Additional repairs were made to the electrical system: replacement of dry transformer with new stainless steel enclosed transformer and replacement of excessively corroded components with new stainless steel components. The interior and exterior of the tank were spot-coated in areas where corrosion was observed, and the non-slip surface on the tank roof was replaced for safety of personnel working on the tanks in the future.