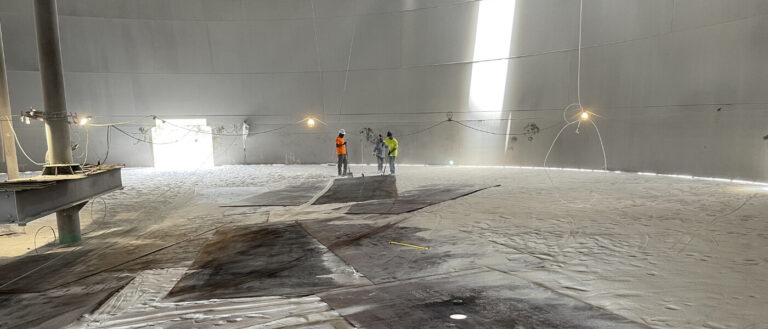

Weston completed this $3.7M firm fixed price project to clean, inspect, and repair Tanks LP-39 and LP-42 (Naval Air Station Chambers Field) and Tanks 3825, 3845, and 3846 (Joint Expeditionary Base [JEB] Little Creek). Weston performed abrasive blasting, coating, and associated internal and external pipe repairs on all tanks at both locations. For each tank at JEB Little Creek, Weston installed new engineered flexible ball joints to manage the expansion of transfer piping, new thickened insert plates for issue and receipt piping, and new water draw off piping. Our team replaced motor operated valve actuator with a new MX-6 Limitorque valve actuator, including wiring, at Tank 3825. At Chambers Field, we performed concrete tank repairs and carefully removed tank coating by surface grinding 100% of the shell and tank bottom without damaging the existing gunite surfaces. This approach to fully remove the existing coating created a clean, smooth surface to be sealed and coated. Weston installed injection ports at the shell to bottom concrete joints cove, injected hydrophobic polyurethane, constructed new coves, applied new Modified Polysulfide coating, and performed hydrostatic testing. At both locations, we installed new slotted stilling wells and commissioned and tested installed components.